|

Listen & Learn

Getting your Trinity Audio player ready...

|

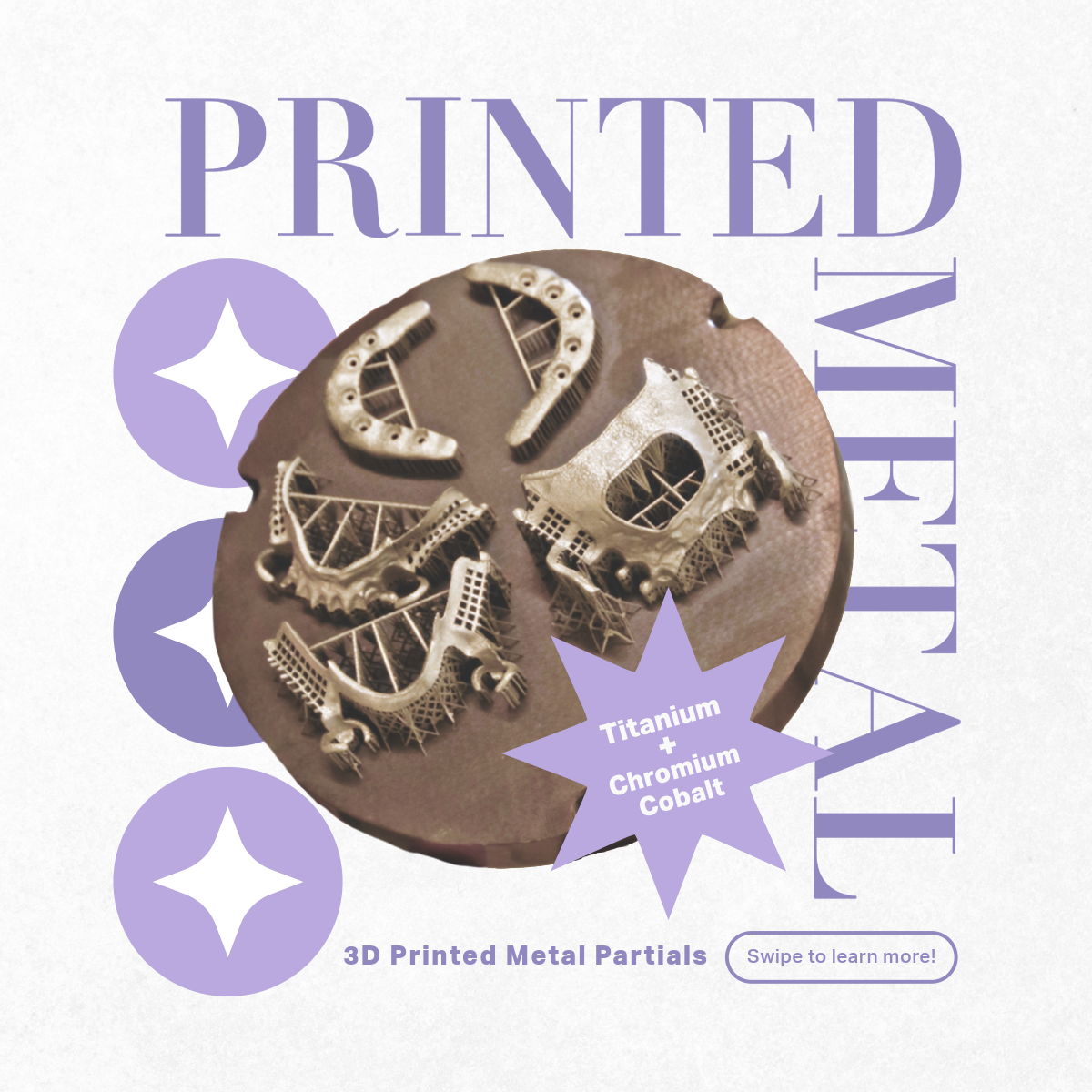

We are thrilled to announce our latest advancement in dental technology at Olivia Dental Lab: 3D Printed Metal Partials. As a leader in the dental industry, we understand the importance of staying at the forefront of innovation to provide you with the best solutions for your patients. With our state-of-the-art Direct Metal Laser Sintering (DMLS) technology, we are revolutionizing the way metal parts are produced for dental applications.

What is DMLS, you might ask? DMLS, also known as Selective Laser Sintering (SLS), is a groundbreaking metal additive manufacturing process, commonly referred to as 3D printing. It allows for the rapid prototyping and mass production of intricate metal parts, including dental restorations.

The process of DMLS follows a simple yet ingenious sequence: model, slice, and print layer-by-layer. First, a 3D model is created using advanced software, and then it is sliced into precise layers. This sliced code is then supplied to the DMLS printer, which initiates the physical printing process.

To begin the printing process, the printer is filled with the desired metal powder, which is heated to a temperature near the sintering range of the alloy. The printer employs an inert gas to protect the heated powder and the part as it is being built.

The actual printing process starts with the dispensing of a thin layer of metal powder onto the build platform. A laser then selectively sinteres the powder in that layer, transforming it into a solid. This dispensing and sintering cycle is repeated until the final part is completed.

Once the printing is finished, the part is left to cool, and any loose metal powder is removed from the printer. The final steps involve support removal and necessary post-processing. The DMLS parts can be further treated through traditional metal working techniques such as machining, heat treatment, or surface finishing.

One of the most remarkable advantages of DMLS is its ability to efficiently produce complex internal and external geometries. Unlike traditional subtractive (machining) or formative (molding) processes, DMLS enables the cost-effective production of intricate designs that were once considered impossible.

Now, you might be wondering how this incredible technology can benefit you and your patients. With our DMLS capabilities, we are pleased to offer you the opportunity to obtain digital metal partials directly from your iTero scan. Through this seamless integration, you can now experience the efficiency, accuracy, and exceptional quality of 3D printed metal partials, ensuring the best outcome for your patients.

At Olivia Dental Lab, we stand by our commitment to using cutting-edge technologies to support your practice and enhance patient care. By introducing 3D Printed Metal Partials into our repertoire, we are excited to offer you a new level of precision and versatility.

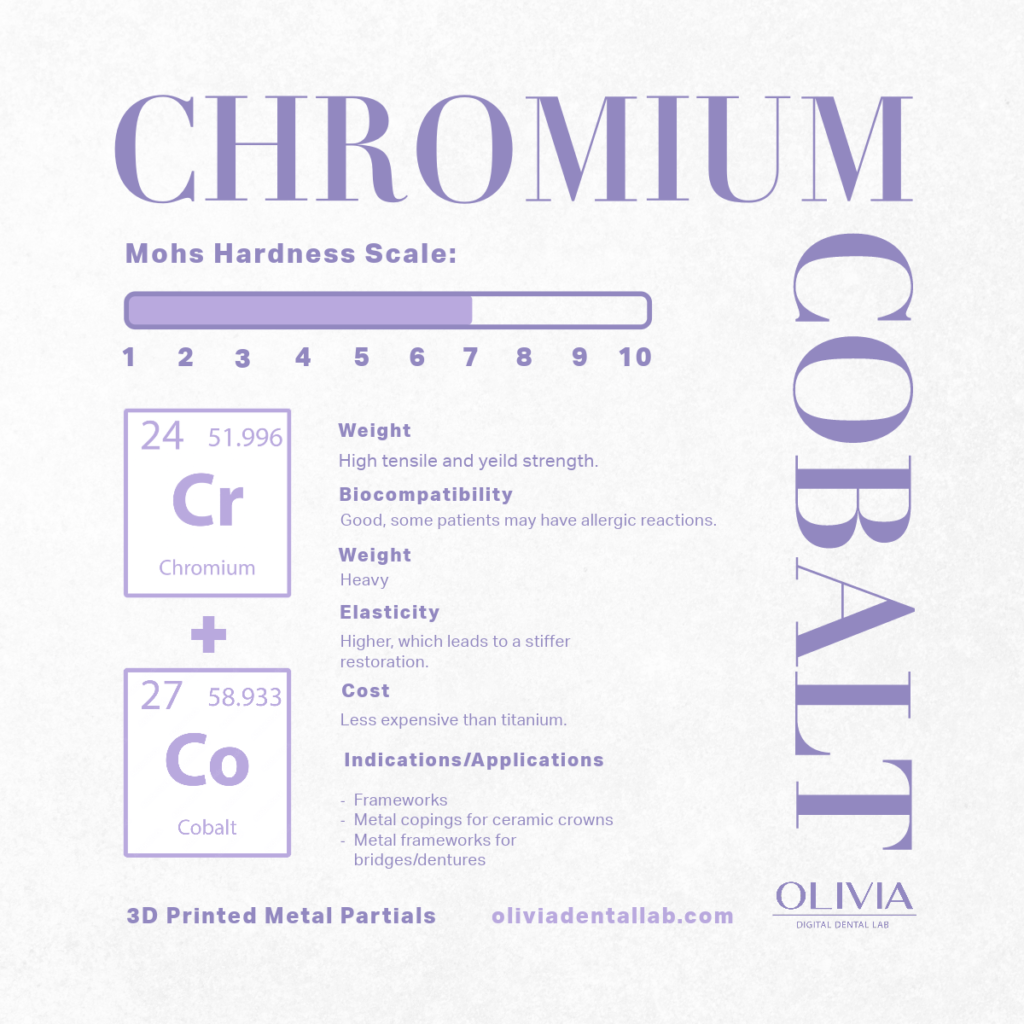

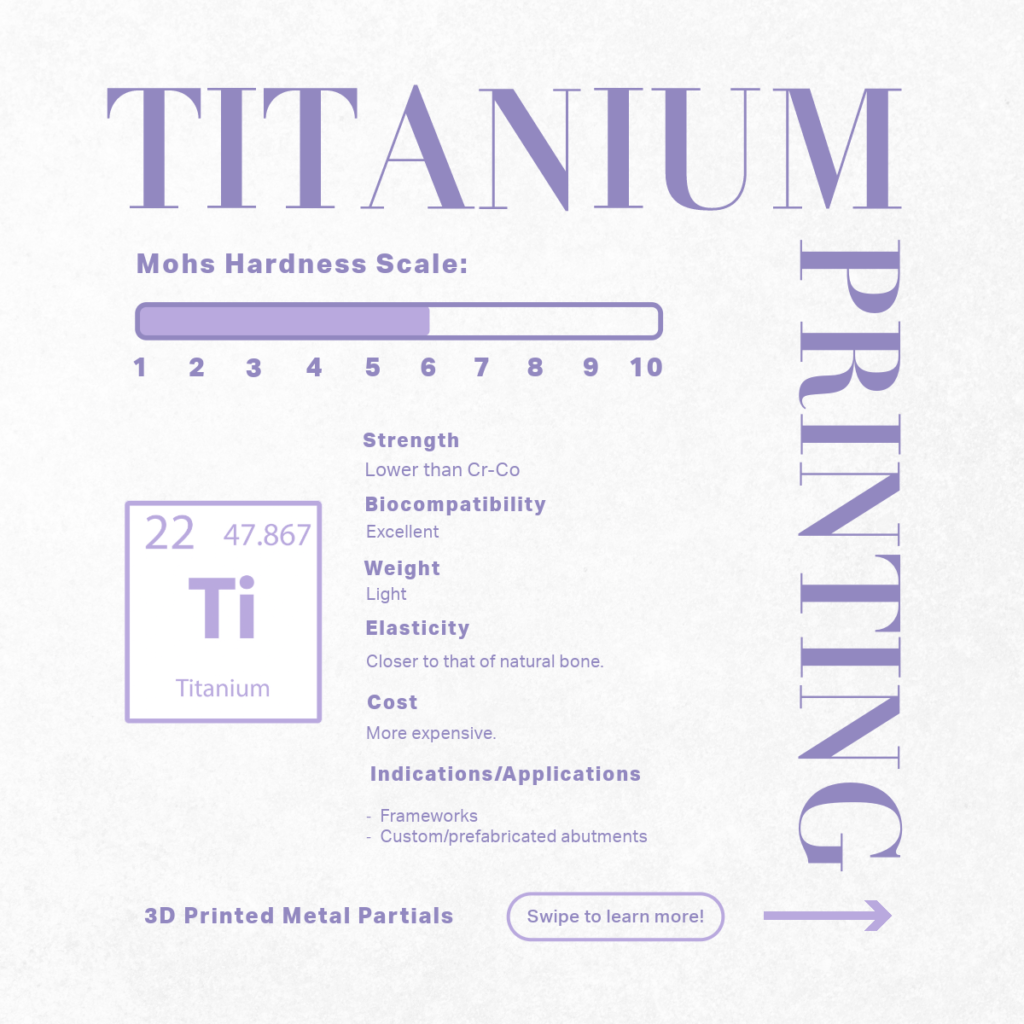

Here is an Infographic with more information about Titanium and Chromium Cobalt’s Indications and strength in dentistry:

We invite you to explore the possibilities of DMLS and discover how this remarkable technology can elevate your dental practice. If you have any questions or would like to learn more about our new services, please do not hesitate to reach out to our knowledgeable team.

Thank you for your continuous trust and partnership in delivering exceptional dental solutions to your patients.

Warmest regards,

Alex

Olivia Dental Lab